SMT placement technology, as an important part of modern electronic manufacturing, provides powerful support for efficient production and miniaturized design of electronic products. By directly mounting electronic components onto the substrate, SMT placement technology not only simplifies the production process but also significantly improves product performance and quality.

Now, let's explore the working principle of SMT placement machines and the advantages of SMT placement processing together with Hunan Charmhigh Electromechanical. Interested friends, please join us in learning more about it.

The advantages of SMT placement technology lie in its efficiency, low cost, and high integration. Compared to traditional through-hole technology, SMT placement eliminates the need for drilling holes on the substrate, significantly reducing the production cycle. Additionally, due to the small size and light weight of SMT components, the overall occupied space of the product is greatly reduced, meeting the market demand for miniaturized and lightweight products. Furthermore, SMT placement technology improves the reliability and stability of electronic products, reducing product failure rates.

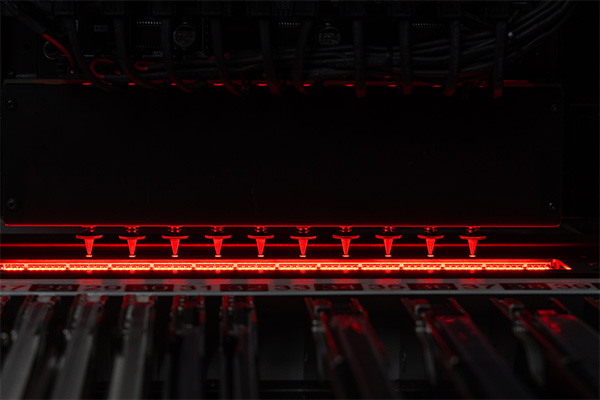

In terms of its working principle, SMT placement technology relies on the design and manufacturing of new electronic components. These SMT components have bottom pins that can be directly connected to the metal traces on the substrate. This connection method simplifies production steps while enhancing the reliability and stability of the connections. Furthermore, SMT placement technology utilizes precision placement machines and accurate positioning technology to ensure that each component is accurately mounted at the designated position on the substrate.

With the continuous development of technology, SMT placement technology will continue to play a crucial role in the electronic manufacturing industry. As the functionality and performance of electronic products continue to increase, the requirements for SMT placement technology will also rise. In the future, SMT placement technology will develop towards higher precision, higher efficiency, and lower costs, injecting new momentum into the development of the electronics industry.

In conclusion, SMT placement technology plays an indispensable role in the electronic manufacturing industry due to its unique advantages and technical principles. By deeply understanding the principles and applications of SMT placement technology, we can better apply it to actual production, driving the continuous development and progress of the electronics industry.

For more knowledge about SMT placement technology, please follow relevant platforms such as Lingzhuo PCBA. We will provide you with the latest technological and industry developments, helping you better grasp the trends and application prospects of SMT placement technology.

Hunan Charmhigh Electromechanical is a professional manufacturer of placement machines. If you have a demand for SMT placement machines, please contact us, and we will provide you with efficient and professional services. If you are interested in becoming our local dealer, we will offer you mutually beneficial and win-win agency solutions.WhatsApp : +8618100733752 / WeChat : 86 18100733752 / Skype : 86 18100733752