SMT (Surface Mount Technology) plays a pivotal role in modern electronic manufacturing, with its efficient and precise assembly methods driving the miniaturization of electronic products and significantly enhancing their reliability. Among the various processes, SMT placement machines stand out as the core equipment on the production line due to their unique functions and performance.

Below, Charmhigh Electromechanical explores the advanced SMT placement technology, focusing on the critical role of SMT placement machines in production lines and fault analysis for optimization. Interested friends, please join us in understanding more.

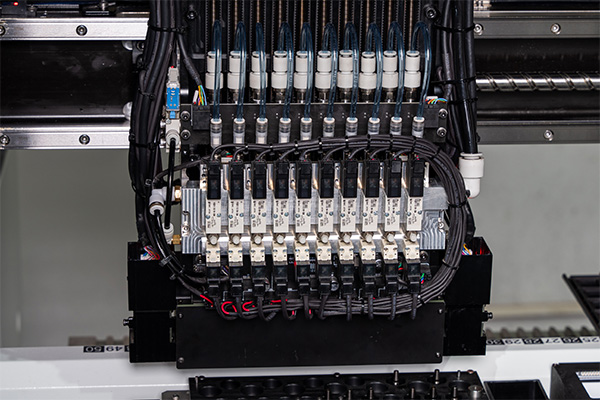

SMT placement machines serve as a critical link in SMT production lines, tasked with precisely and rapidly mounting electronic components onto PCB boards. The accuracy of this process directly determines the quality and performance of the product. However, in actual production, SMT placement machines may encounter various faults, such as nozzle blockage, decreased positioning accuracy, etc. These faults not only affect production efficiency but may also lead to product quality issues.

To effectively address faults in SMT placement machines, it is essential to have a deep understanding of their working principles and common fault types. Through various methods such as visual inspection, testing analysis, and data analysis, we can promptly detect and resolve issues that arise during the operation of SMT placement machines. For instance, visual inspection can intuitively detect component offset or missing components; testing analysis utilizes professional equipment to perform functional testing on PCB boards, revealing potential welding defects; and data analysis collects and analyzes production data to identify the patterns and causes of faults, providing strong support for production optimization.

In terms of preventing SMT placement machine faults, we should also adopt a series of effective measures. Firstly, strengthen routine maintenance and servicing of the equipment to ensure its stability and accuracy. Secondly, select high-quality electronic components and PCB boards to avoid faults caused by material issues. Additionally, optimizing process parameters, adjusting placement speed and accuracy based on product characteristics and equipment performance, is also an effective way to reduce fault rates.

In conclusion, SMT placement machines play a crucial role in SMT production lines. Having a deep understanding of their working principles and common fault types, and adopting effective troubleshooting methods and preventive measures, are of great significance for improving the stability of production lines and product quality. In the future of electronic manufacturing, with the continuous advancement of technology and the expansion of application fields, SMT placement machines will continue to play a greater role, driving the sustained development of the electronic manufacturing industry.

Charmhigh Electromechanical is a professional SMT placement machine research, development, and manufacturing company. If you have a need for SMT placement machines, please contact us, and we will provide you with efficient and professional services. If you are interested in becoming our local dealer, we will provide you with mutually beneficial and win-win agency programs.WhatsApp : +8618100733752 / WeChat : 86 18100733752 / Skype : 86 18100733752