As a crucial equipment in the electronic manufacturing process, the mounting efficiency of SMT placement machines directly affects the operational efficiency of the entire production line. However, many users have found that after using the placement machine for a certain period, its mounting efficiency gradually decreases. So, what are the reasons behind this issue? Hunan Charmhigh Electromechanical would like to discuss this with you. Interested friends, please join us in understanding the reasons.

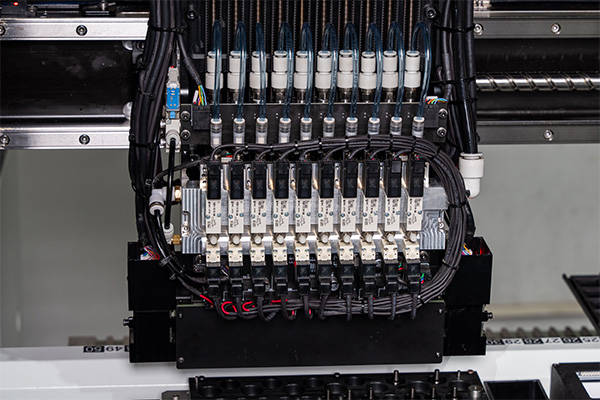

Firstly, the nozzle issue of the placement machine is a factor that cannot be ignored. Insufficient vacuum negative pressure of the nozzle or pressure relief in the air source circuit may cause the nozzle to fail to stably pick up and place components. Additionally, wear and tear of the nozzle after extended use, as well as dust and debris from the external environment, can lead to nozzle blockage, further affecting mounting efficiency.

Secondly, errors in the programming settings of the placement machine also contribute to decreased mounting efficiency. If the programming is not set properly or optimized according to specific production needs, it may result in deviations or errors during the mounting process, thereby reducing efficiency.

Lastly, the quality of electronic components themselves can also impact mounting efficiency. If the pins of the components are not made to specification or do not meet quality standards, it may lead to incomplete insertion of the pins or issues such as bending or breaking during the mounting process. This not only affects mounting efficiency but also severely impacts product quality.

To address these issues, we can adopt a series of solutions to improve the mounting efficiency of the placement machine. Firstly, regularly inspect and maintain the placement machine to ensure the proper functioning of the nozzle and air source circuit. Secondly, strengthen training for operators to improve their skill level and operational proficiency, thus reducing programming errors. Finally, strictly control the quality of electronic components and select reliable suppliers with standardized manufacturing practices to ensure smooth mounting processes.

In conclusion, there are various reasons for the decreased mounting efficiency of SMT placement machines. However, by adopting corresponding solutions and measures, we can effectively improve the mounting efficiency of the placement machine, thereby enhancing the operational efficiency of the entire production line.

Hunan Charmhigh Electromechanical is a professional manufacturer specializing in the research and development of placement machines. If you have a demand for SMT placement machines, please contact us, and we will provide you with efficient and professional services. If you are interested in becoming our local dealer, we will offer you mutually beneficial and win-win agency solutions.WhatsApp : +8618100733752 / WeChat : 86 18100733752 / Skype : 86 18100733752