With the rapid development of technology, electronic devices such as smartphones and tablets are pursuing extreme thinness and lightness. In SMT technology, electronic components have shrunk from 0402 to 0201 sizes, making solder joint quality a crucial factor. Solder joints, as the linkage between electronic components and PCBs, directly affect the quality of the device. Ensuring the quality of solder joints is an important issue in high-precision patch processing. Let's delve into this topic with Charmhigh Electromechanical.

In the SMT patch processing flow, cold soldering is a common and critical issue that can directly affect the performance and quality of electronic devices. Therefore, it is essential to detect and address cold soldering promptly.

To ensure the quality of solder joints, we can use professional equipment such as in-circuit testers for detection, combined with visual inspection or the use of AOI equipment for detailed examination. Once signs of insufficient soldering material, poor solder wettability, solder joint fractures, or abnormal solder surface are detected, they must be taken seriously. These seemingly minor issues may hide the risk of batch cold soldering, which, if ignored, can lead to decreased device performance or even failure.

So, what are the root causes of cold soldering issues and how can we effectively resolve them?

Firstly, unreasonable solder pad design is a common cause. For instance, the presence of through-holes in the solder pad can lead to solder loss and material insufficiency. Therefore, during the design stage, we should avoid using solder pads with through-holes and ensure that the solder pad parameters comply with specifications.

Secondly, oxidation or contamination of the PCB board is also an important factor leading to cold soldering. Surface oxide layers or contaminants can affect the wettability and adhesion of the solder. To address this, we can use a rubber eraser to remove the oxide layer or a cleaning agent to eliminate contaminants, ensuring a clean surface of the PCB board.

Lastly, scraping of the solder paste during the processing is also a common issue. This can reduce the amount of solder paste on the solder pad, affecting the quality of soldering. To address this, we should promptly replenish the solder paste to ensure sufficient soldering material at the solder joints.

In conclusion, the issue of cold soldering in SMT patch processing deserves serious attention. By adopting professional testing equipment and scientific solutions, we can promptly detect and address cold soldering phenomena, ensuring the overall quality and stability of electronic devices.

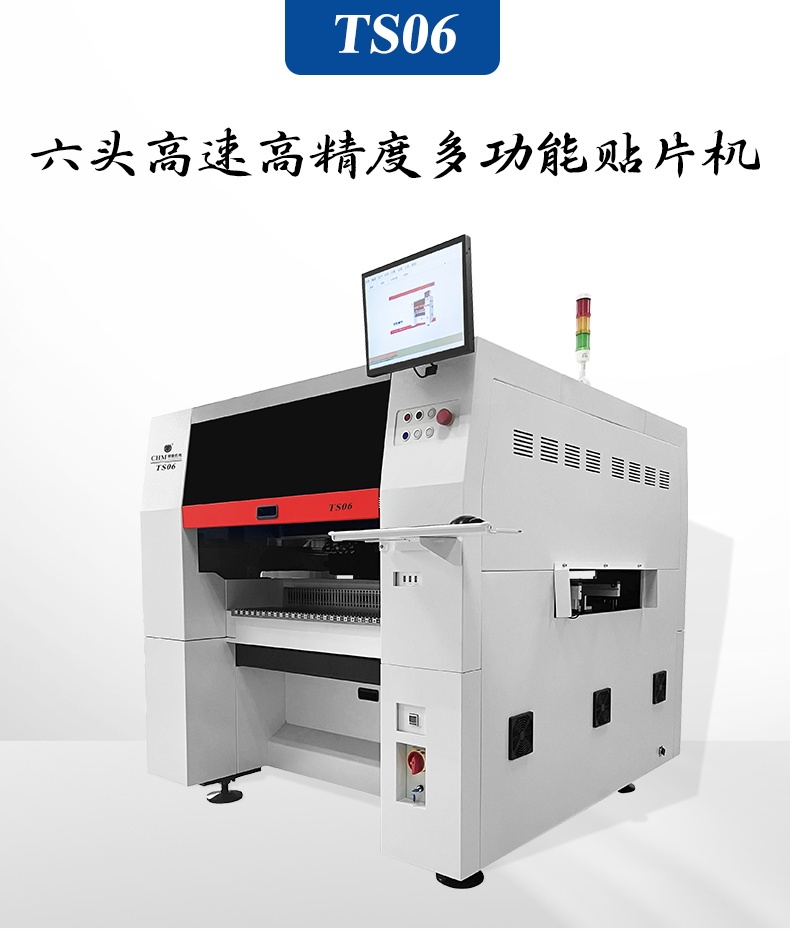

Hunan Charmhigh Electromechanical is a professional manufacturer specializing in the development and production of SMT placement machines. If you have a demand for SMT placement machines, please contact us, and we will provide you with efficient and professional services. If you are interested in becoming our local dealer, we will offer you mutually beneficial and win-win agency solutions.WhatsApp : +8618100733752 / WeChat : 86 18100733752 / Skype : 86 18100733752