SMT (Surface Mount Technology) plays a pivotal role in the electronic manufacturing industry, and reflow soldering, as a crucial step in SMT processing, directly affects the reliability and performance of products. Here, Charmhigh Electromechanical will discuss the potential impact of reflow soldering on SMT processing quality and the key factors involved, inviting interested parties to learn more about it.

PCB Deformation Caused by Temperature Gradient

Reflow soldering requires exposing the PCB and components to high temperatures to melt the solder and form sturdy solder joints. However, the significant temperature difference between different regions on the PCB can lead to PCB deformation. PCB deformation not only affects the quality of the solder joints but also may damage or displace components, thereby affecting the overall performance of the product.

To mitigate the adverse effects of temperature gradients, manufacturers have adopted various measures. For example, increasing the thickness of the PCB or using more heat-resistant materials can improve the thermal stability of the PCB. Additionally, optimizing the temperature distribution and heating rate of the reflow soldering equipment can effectively reduce temperature gradients and improve welding quality.

Component Damage Caused by Temperature Gradient

Components used in SMT processing are often tiny and precise, making them highly sensitive to temperature changes. Excessively high temperatures may damage components, such as melting plastic housings and damaging internal circuits. Therefore, it is crucial to strictly control the temperature during the reflow soldering process to ensure that components are welded within an appropriate temperature range.

Oxidation During Reflow Soldering

Solder is prone to reacting with oxygen in the air at high temperatures, forming metal oxides. These oxides can affect the quality of the solder joints and may cause loose or broken connections between the solder joints and the PCB. To mitigate the adverse effects of oxidation, manufacturers often employ measures such as nitrogen protection to reduce the oxygen content in the air and reduce the occurrence of oxidation reactions.

The impact of reflow soldering on SMT processing quality is multifaceted. By optimizing reflow soldering processes and equipment parameters, strictly controlling temperatures, and reducing oxidation, the reliability and performance of SMT processing can be effectively improved.

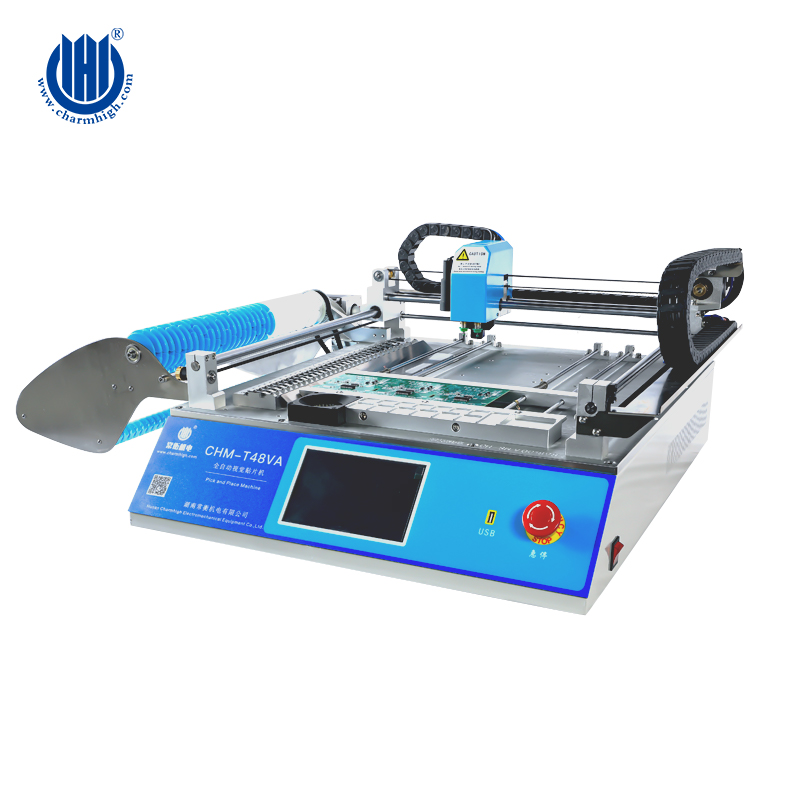

Hunan Charmhigh Electromechanical is a professional manufacturer of SMT placement machines. If you have a need to purchase SMT placement machines, please contact us, and we will provide you with efficient and professional services. If you wish to become our local dealer, we will offer you mutually beneficial and win-win agency solutions.WhatsApp : +8618100733752 / WeChat : 86 18100733752 / Skype : 86 18100733752