The SMT (Surface Mount Technology) production line is an integral part of modern electronics manufacturing, and its working environment requirements directly affect the stability of the production process and product quality. To ensure the smooth operation of the SMT production line, Charmhigh Electromechanical has compiled several key requirements for the working environment of the SMT production line. Interested parties can take a look together.

Temperature

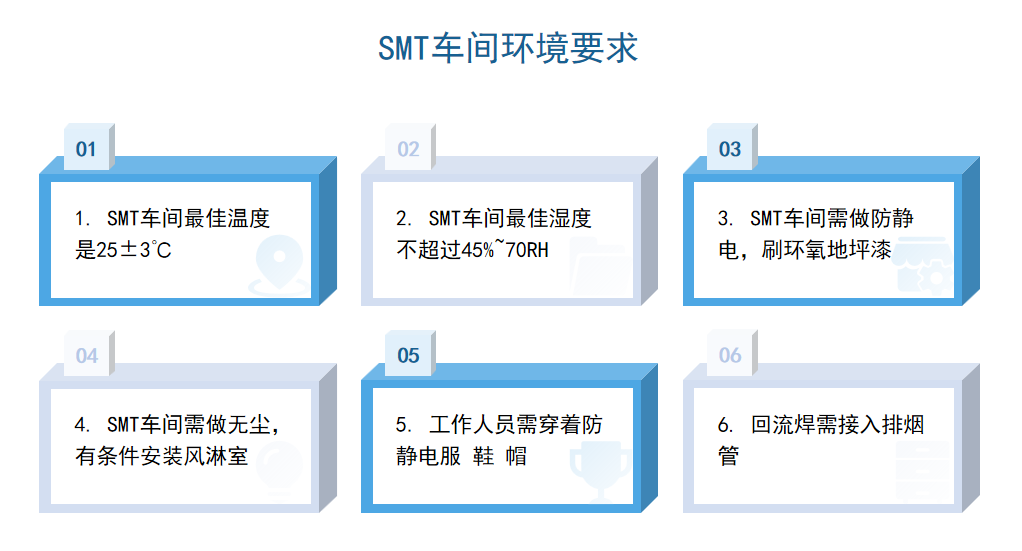

The working environment of the SMT production line should be maintained within a suitable temperature range, typically 23℃±3℃, to ensure the stable operation of the placement machine and welding quality. Excessively high or low temperatures may affect the performance of the equipment and welding results.

Humidity

Appropriate humidity can reduce the absorption of moisture by components and the generation of static electricity, thereby improving welding quality and equipment reliability. Generally, the relative humidity of the working environment should be controlled between 45% and 70%RH to ensure the stability of the production environment.

Air Cleanliness

The working environment should be kept clean, free of dust, corrosive gases, and odors. Dust and chemicals in the air may adversely affect the placement and welding of tiny components. Therefore, the air cleanliness must meet certain standards.

In addition to the above three factors, air pressure, power supply, and lighting are also areas that need attention. The air pressure should be maintained between 0.5 and 1 atmosphere, the power supply voltage and power should meet the equipment requirements, and the lighting conditions should be sufficient and uniform to reduce operator fatigue and improve work efficiency.

Finally, safety measures are also essential. The working environment should be equipped with corresponding safety equipment and signage, such as anti-static flooring, fire extinguishing equipment, etc., to ensure the safety of operators and equipment.

Creating a high-quality working environment is the key to ensuring the stable operation of the SMT production line and improving product quality. Only by meeting these requirements can we fully utilize the potential of the SMT production line and achieve efficient and precise production goals.

Hunan Charmhigh Electromechanical is a professional placement machine R&D and manufacturing enterprise. If you have a need to purchase SMT placement machines, please contact us, and we will provide you with efficient and professional services. If you wish to become our local distributor, we will offer you a mutually beneficial agency solution.WhatsApp : +8618100733752 / WeChat : 86 18100733752 / Skype : 86 18100733752