Charmhigh Electromechanical today will discuss with you that in SMT patch processing, printing failures are one of the main factors affecting product quality. According to statistics, up to 60% of defects are caused by solder paste printing issues. Therefore, taking effective measures to avoid these failures is crucial for ensuring the quality of SMT patch processing.

The selection of molds and PCB printing methods is crucial. Touch printing, due to its high precision and stability, is particularly suitable for high-precision solder paste printing. Additionally, printing speed, method, and squeegee type are also key factors affecting printing quality. Appropriately increasing the printing speed can reduce solder paste leakage and rolling, improving printing accuracy. Simultaneously, choosing the appropriate printing method (such as non-contact printing) and squeegee type (such as steel squeegees) can further improve printing results.

The selection of mounting height is also an important measure to avoid SMT printing failures. For ICs with small spacing, an appropriate mounting height should be chosen to avoid solder paste collapse and short circuits during reflow due to excessively low mounting heights.

Attention should also be paid to avoiding failures during reflow soldering. Factors such as too fast temperature rise, excessively high heating temperature, mismatch between solder paste and PCB heating speeds, and excessive water flow can all lead to assembly failures. Therefore, when determining reflow soldering process parameters, these factors should be fully considered to ensure welding quality.

Avoiding SMT printing failures requires a multifaceted approach. By selecting appropriate printing methods, adjusting printing parameters, optimizing mounting heights, and controlling the reflow soldering process, the rate of printing failures in SMT patch processing can be significantly reduced, improving product quality.

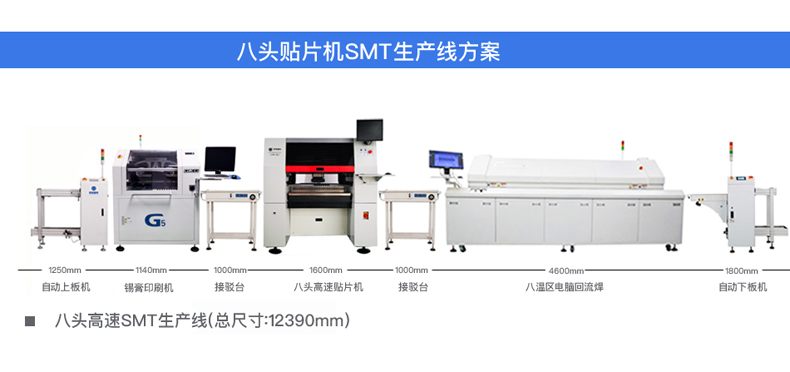

Hunan Charmhigh Electromechanical is a professional SMT placement machine R&D and manufacturing enterprise. If you have SMT placement machine purchase needs, please contact us, and we will provide you with efficient and professional services. If you wish to become our local distributor, we will provide you with mutually beneficial agency solutions.WhatsApp : +8618100733752 / WeChat : 86 18100733752 / Skype : 86 18100733752