Today, Charmhigh Electromechanical would like to discuss with you the possible reasons for component displacement in SMT chip processing. SMT chip processing is a commonly used component installation method in electronic manufacturing, but sometimes issues such as component displacement may occur. Let's introduce some possible reasons for SMT chip processing component displacement.

In SMT chip processing, component displacement is a common challenge, which can be caused by various factors. Among them, incorrect solder paste application is an important reason. Solder paste plays a crucial role in adhering SMT components to the PCB. If the solder paste distribution is uneven or the position is inaccurate, it will cause the components to shift during the soldering process.

Besides the solder paste issue, the accuracy of component positioning is also crucial. If the components are not correctly aligned with the pads on the PCB on the placement machine, displacement is difficult to avoid. This may be due to equipment failure, inaccurate calibration, or issues with the components themselves.

Moreover, the quality of the components themselves is also an important factor affecting displacement. Issues such as uneven pins, irregular packaging, or skewness can all cause the components to be unstable during the soldering process, resulting in displacement.

During the SMT soldering process, thermal stress and temperature changes may also cause component displacement. Due to the high temperatures involved in the soldering process, thermal stress is generated between the PCB and the components, affecting the positional stability of the components.

Vibration and mechanical shock on the production line are also factors that cannot be ignored. Equipment such as conveyor belts and placement machines may generate vibration and shock during operation, which can interfere with the position of the components.

To reduce the risk of component displacement in SMT chip processing, we need to strengthen process control, ensure the accuracy of equipment calibration, and strictly screen component quality. At the same time, the maintenance and upkeep of production line equipment are also crucial to reduce the impact of vibration and mechanical shock on component positions.

In conclusion, component displacement in SMT chip processing is a problem that requires comprehensive consideration of multiple factors. By optimizing processes, improving equipment accuracy, and strengthening quality management, we can effectively reduce the risk of component displacement and improve production efficiency and product quality.

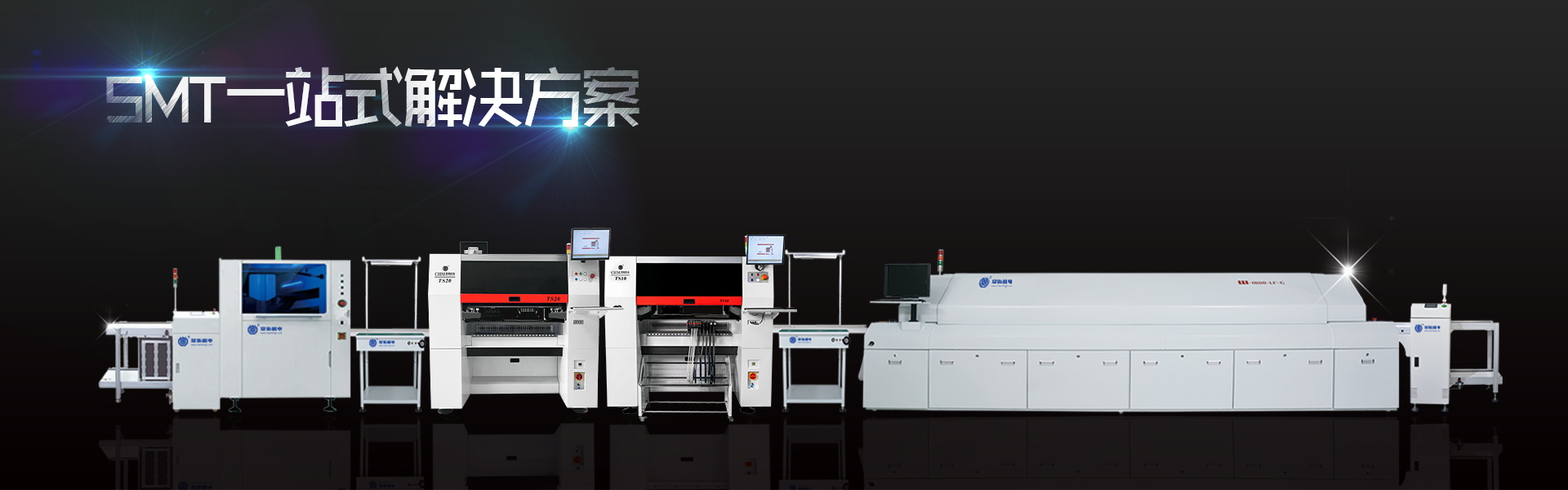

Hunan Charmhigh Electromechanical is a professional manufacturer of SMT placement machines. If you have a need for SMT placement machines, please contact us, and we will provide you with efficient and professional services. If you are interested in becoming our local distributor, we will provide you with mutually beneficial agency solutions.WhatsApp : +8618100733752 / WeChat : 86 18100733752 / Skype : 86 18100733752