SMT chip processing is a precise and highly focused manufacturing process, with each step potentially having significant impacts on the final product quality. Here are the key considerations in SMT chip processing compiled by Charmhigh Electromechanical.

Pre-Printing Verification and Preparation:

Carefully verify the compatibility of the stencil, PCBA, solder paste, and other necessary tools and fixtures to ensure accuracy.

Inspect the stencil holes for cleanliness, ensuring no residual solder dross or other foreign objects. Ensure the board surface is also clean and free of dirt.

Solder Paste Selection and Handling:

Confirm that the solder paste brand, model, and specifications match the process requirements.

Strictly follow the specified procedures for solder paste tempering and stirring to ensure it is in the best condition for use.

Printer Parameter Setting and Adjustment:

Properly place the stencil and fixtures on the printer and precisely adjust all parameters to match the actual process needs.

Pay attention to key parameters such as squeegee angle, printing speed, squeegee pressure, and demolding speed to achieve the best printing results.

PCBA Quality and Handling:

Before production, carefully inspect the PCBA for deformation, damage, foreign objects, or oxidation, and gently wipe its surface with a dust-free cloth.

For poor-quality products, use appropriate cleaning methods to remove the solder paste from the board surface and perform necessary baking treatment.

Stencil Cleaning and Maintenance:

Regularly manually clean the stencil during production to ensure stable printing quality.

Use a dust-free paper dipped in an appropriate amount of cleaning solution to wipe the bottom of the stencil and use a tool to blow away residual solder paste in the holes.

Based on production conditions, timely feedback and adjustment of the stencil status are essential to ensure smooth continuous production.

Good Product Management and Identification:

Store good products with layers to avoid contamination or damage.

Fill in detailed machine type and work order status information on the process indication card for easy tracking and management.

Post-Printing Management and Control:

Strictly control the stacking time of PCBAs after SMT processing to avoid quality issues caused by excessive time.

When adding solder paste, pay attention to controlling the squeegee rolling volume and promptly collect any spilled solder paste to avoid waste.

Working Environment and Safety:

During the operation, turn off the lighting when appropriate to reduce distractions for operators.

Engineering personnel should regularly check the blade wear condition to ensure printing quality and operational safety. It is generally recommended to replace the blade every six months.

By strictly implementing these considerations, the SMT chip processing process can be ensured to proceed smoothly, improving product quality and production efficiency. It can also help reduce production costs and reduce the rejection rate, enhancing the overall competitiveness of the enterprise.

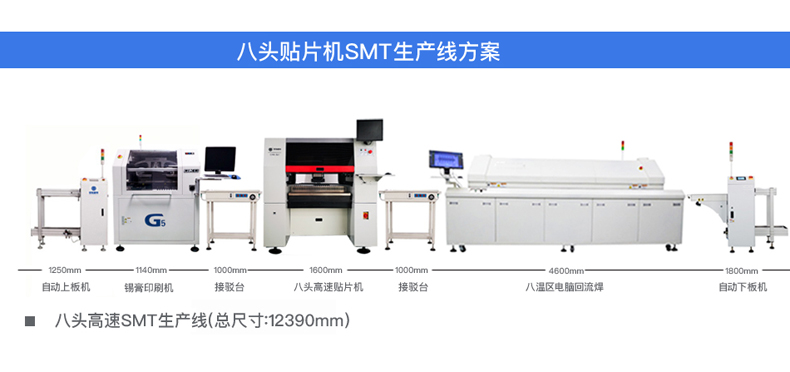

Hunan Charmhigh Electromechanical is a professional SMT placement machine R&D and manufacturing company. If you have a need for SMT placement machines, please contact us, and we will provide you with efficient and professional services. If you are interested in becoming our local distributor, we will offer you mutually beneficial agency solutions.WhatsApp : +8618100733752 / WeChat : 86 18100733752 / Skype : 86 18100733752