In the wave of electronics manufacturing, SMT chip processing has occupied a pivotal position due to its high efficiency and precision. However, during this process, challenges such as poor assembly and welding errors inevitably arise, affecting the final quality and performance of the product. Therefore, mastering the common detection and repair methods of SMT chip processing is crucial to ensuring product quality. Here, Charmhigh Electromechanical explores the detection and repair techniques of SMT chip processing, and we invite interested parties to join us in understanding them.

During SMT chip processing, poor assembly and welding errors are two common issues. Poor assembly may lead to unstable welding, misaligned components, and affect product stability and reliability. On the other hand, welding errors may include incorrect welding positions, poor welding contact, and directly impact the product's functionality.

To promptly identify these issues, we can employ various detection methods. Visual inspection, with its high efficiency and accuracy, can quickly identify assembly defects and welding errors. X-ray inspection, as a non-destructive testing method, can penetrate into the interior of components to detect the quality of solder joints and component positions. Additionally, infrared detection is a non-destructive testing method that can monitor welding temperature and quality in real-time, providing robust support for the welding process.

Once issues are discovered, we need to take prompt repair measures. For component problems, we can reinstall or repair components using hot air guns or manual disassembly methods. For welding issues, we can perform re-welding, replace solder joints, and other operations to ensure welding quality.

In conclusion, the detection and repair work in SMT chip processing cannot be neglected. By employing various detection methods to promptly identify problems and taking effective repair measures to fix them, we can ensure that the quality and performance of the product reach their optimal state.

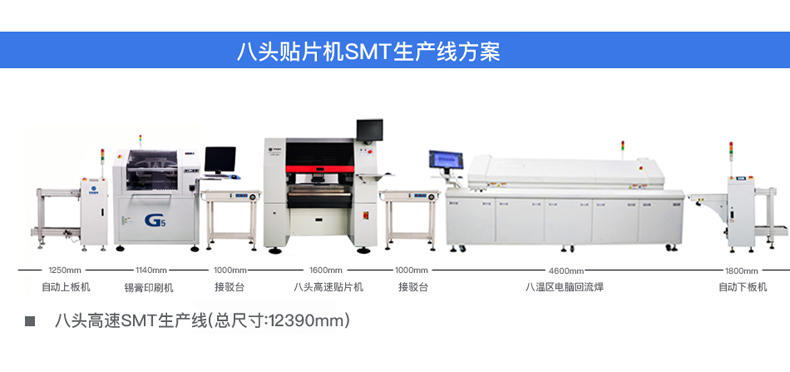

Hunan Charmhigh Electromechanical is a professional manufacturer of SMT placement machines. If you have a need for SMT placement machines, please contact us, and we will provide you with efficient and professional services. If you are interested in becoming our local distributor, we will offer you mutually beneficial agency solutions.WhatsApp : +8618100733752 / WeChat : 86 18100733752 / Skype : 86 18100733752